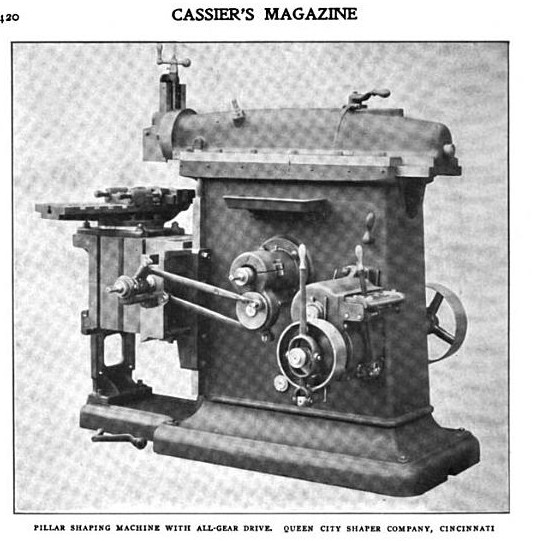

Turbinedoctor wrote:Is a shaper really all that much better than a mill? What are the selling points other than having spare time on your hands and wanting to restore a nice old cool piece of machinery?

Durwood

That's a really good question. As I understand them the answer is pretty much "No", a shaper is not better than a mill. Now, that being said, there are a few things that the shaper excels at compared to a mill. You can follow a curve, cut gears, produce flat surfaces, and cut splines using very inexpensive cutting tools (pretty much like the HSS lathe bits). The downside on even these operations though is that the shaper is slow. If you are in a production environment or being paid on the clock they won't make a whole lot of sense.

I suppose if a person were knowledgeable enough on the shaper he could accomplish most of the operations being done on a mill but it would take a lot more thought and creative setup to get them done, as well as time. Then there are things that a mill can do that a shaper just can't (at least I can't think of a way). Things like plunging in with an endmill and hollowing out a "box" or any other operation that would be like "drilling a blind hole" or boring.

Now, I guess, for the "why?". In my case I like machines. I like working with old tools and doing things the "old way". It's the same way that I prefer to play pinball machines instead of video games or hunt with a longbow as opposed to a modern compound bow or rifle. It's much the same as why most of us use manual lathes and mills instead of going with CNC (other than the cost of equipment) but it's just taking a bit bigger step "back". There are guys that use treadle lathes or take out a file and turn a block of steel into a precise flange or some such. I don't know why it is but I have more respect for the guys that can do that kind of thing than I do for someone who learned how to program the machine to do it (I spent 25 years as a computer programmer btw.

) In all I think it's just trying to have some kind of connection with the guys I respected (like my grandfather) who did things "the hard way".

Bit of a ramble but I hope that made some kind of sense. Don't get me wrong though, I'm not some kind of masochist either and I'm still looking/planning on getting a decent mill as well.

-Ron

http://www.mcmaster.com/#crank-handles/=g5vn6f

http://www.mcmaster.com/#crank-handles/=g5vn6f