Re: Where are we at?

Making some progress! I received the inserts to go in the Aloris #71 parting tool. With a great deal of trepidation  I set the SB up for parting and gave it a shot -

I set the SB up for parting and gave it a shot -

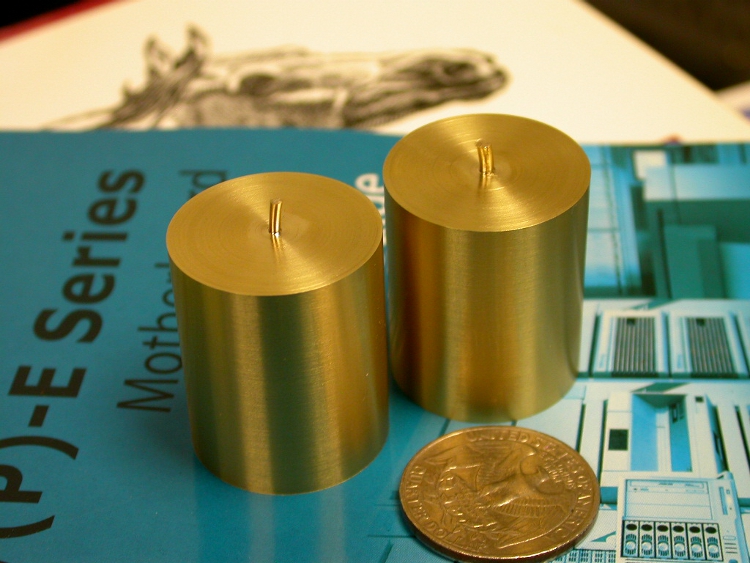

As this was the first time I've ever tried parting with a carbide insert I have to admit I was a bit surprised by how well they came out. These pics are just how they dropped from the lathe, the "nubs" are still on. I was using a "flat" insert which I believe was the cause of the nubs. I understand now why they offer both a left and right angled bits as well. I fed the the cutter by hand but also used a live center in the tailstock to keep everything as rigid as possible.

I had "planned" to get 3 cylinders parted from the round stock I had in the chuck but I initially mis-read (or just forgot) the plans and planned on making them 1" tall when they were actually to be 1.19" tall. At least I double checked what the proper size should be before I made the first cut.

the plans and planned on making them 1" tall when they were actually to be 1.19" tall. At least I double checked what the proper size should be before I made the first cut.

Things are gettling back to ("ab-"?) normal around here so I am pretty sure I'll have the rest of the cylinders turned and parted in the next few days then it will be on to the milling, drilling, and boring. How are you doing Rleete?

-Ron

As this was the first time I've ever tried parting with a carbide insert I have to admit I was a bit surprised by how well they came out. These pics are just how they dropped from the lathe, the "nubs" are still on. I was using a "flat" insert which I believe was the cause of the nubs. I understand now why they offer both a left and right angled bits as well. I fed the the cutter by hand but also used a live center in the tailstock to keep everything as rigid as possible.

I had "planned" to get 3 cylinders parted from the round stock I had in the chuck but I initially mis-read (or just forgot)

Things are gettling back to ("ab-"?) normal around here so I am pretty sure I'll have the rest of the cylinders turned and parted in the next few days then it will be on to the milling, drilling, and boring. How are you doing Rleete?

-Ron

Shame on you.

Shame on you.