Since even a Kurt vise has some lift when you tighten it, could you use one parallel against the fixed jaw to position the piece, then remove the parallel when the vise is tight? I've done that sort of thing with the clone vises and didn't notice the work shifting.

The edges of the V in the vise jaw could leave lines in the side of the piece. Would a strip of aluminum from a drink can prevent the lines while still leaving enough gripping power?

Where are we at?

Re: Where are we at?

Mike

-

Hawkeye - Posts: 44

- Joined: Sun Feb 05, 2012 10:04 pm

- Location: Kelowna, BC, Canada

Re: Where are we at?

You need to use some soft material (soda can, as mentioned above is a good choice) to protect the part from the vertical V. A single thin parallel should be all you need to get it squared up (along/under the flat side). That should give you enough clearance so as to not drill/bore into anything.

Personally, I wouldn't bother with a V jaw. If that's not perfectly square to the top of the vise, it will hold that part off a tiny bit. It will also mar the part with lines if you tighten it too much. Rely instead on a single parallel under the part to square it up. You can lock the bed in both directions, and use a stop to locate each successive part. That way you don't have to re-indicate each part.

I also would drill to just under 1/2" (31/64 drill if you have it) and use a reamer to bring it smooth and to size. Trying to match each piston to the bore is going to be a royal pain, and really isn't that critical. Anything up to a couple/three thou clearance will still be a runner. Heck, some of my engines are downright sloppy - probably about 5 thou clearance - and they still run quite well.

Personally, I wouldn't bother with a V jaw. If that's not perfectly square to the top of the vise, it will hold that part off a tiny bit. It will also mar the part with lines if you tighten it too much. Rely instead on a single parallel under the part to square it up. You can lock the bed in both directions, and use a stop to locate each successive part. That way you don't have to re-indicate each part.

I also would drill to just under 1/2" (31/64 drill if you have it) and use a reamer to bring it smooth and to size. Trying to match each piston to the bore is going to be a royal pain, and really isn't that critical. Anything up to a couple/three thou clearance will still be a runner. Heck, some of my engines are downright sloppy - probably about 5 thou clearance - and they still run quite well.

Homier Speedway 7x14 lathe

Grizzly G8689 Mini Mill

HF 4x6 Bandsaw, bench grinder and more

Years of experience wrecking things

Grizzly G8689 Mini Mill

HF 4x6 Bandsaw, bench grinder and more

Years of experience wrecking things

- rleete

- Posts: 62

- Joined: Thu Feb 02, 2012 5:22 am

- Location: Rochester, NY

Re: Where are we at?

Thanks for the suggestions guys. I have to admit though that I was a bit surprised by the comments about not using the "V" slot jaws. First of all I think the "V" is large enough so that the cylinder would sit inside the "V" and not come in contact with the edges (I haven't sized it to make sure so it's still theory). I'm figuring that it would distribute the force of the vise better so I wouldn't need to apply as much force to get an equal holding power. The only drawback being that it would have the potential to leave two "flats" on the cylinder body instead of just one with the flat jaw. I was also planning on using a strip of brass shim material to try and protect the cylinders from getting vise marks.

It hadn't occurred to me that the "V" might not be plumb with the vise (still pretty new at this) so I really appreciate the "heads up" on that. Now I will use an indicator to check that before trying to use them. If it is off I'll have to switch to Plan B.

My reason for wanting to use the "V" jaw is the same reason rleete suggested the vise-stop to quickly locate each successive part. The only problem with a vise-stop is that I don't have one. I'd have to make one or cobble something together to serve that purpose whereas I already have the "V" jaw. If it turns out that the "V" is too small to contain the part or it is not "square" then part of "plan B" will include the procurement or making of a vise-stop.

I also came to the realization last night that I wouldn't have to use an edge finder for the "Y" axis. I can indicate the cylinder on three sides, two "X" and one "Y". If all three measurements are the same the quill will be parked right over the "center" of the original cylinder (before the flat) so then I'll I'd have to do is move in the "Y" axis the offset from the original center to the center of the hole for the piston. - Hope that makes sense.

That's my reasoning in a nut shell. If I'm not considering something or am making a mistake whether just a disagreement on procedure or something real fubar don't be shy about bringing it up, I'm still learning and it doesn't hurt my ego to be called out on something.

Thanks guys,

-Ron

It hadn't occurred to me that the "V" might not be plumb with the vise (still pretty new at this) so I really appreciate the "heads up" on that. Now I will use an indicator to check that before trying to use them. If it is off I'll have to switch to Plan B.

My reason for wanting to use the "V" jaw is the same reason rleete suggested the vise-stop to quickly locate each successive part. The only problem with a vise-stop is that I don't have one. I'd have to make one or cobble something together to serve that purpose whereas I already have the "V" jaw. If it turns out that the "V" is too small to contain the part or it is not "square" then part of "plan B" will include the procurement or making of a vise-stop.

I also came to the realization last night that I wouldn't have to use an edge finder for the "Y" axis. I can indicate the cylinder on three sides, two "X" and one "Y". If all three measurements are the same the quill will be parked right over the "center" of the original cylinder (before the flat) so then I'll I'd have to do is move in the "Y" axis the offset from the original center to the center of the hole for the piston. - Hope that makes sense.

That's my reasoning in a nut shell. If I'm not considering something or am making a mistake whether just a disagreement on procedure or something real fubar don't be shy about bringing it up, I'm still learning and it doesn't hurt my ego to be called out on something.

Thanks guys,

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: Where are we at?

If the V is large enough to grip the sides, and not rest on the edges, that's a different animal. I was thinking small (like 1/8") V groove.

The idea of using that to locate instead of a stop is a good one, provided it is a positive location, and not too reliant on "feel" to get successive parts in the same spot. If it is, you can also center the vise before putting in the part, using the V itself, and thereby eliminate trying to indicate off the round sides. Then indicate off the flat side of the jaw, and offset from there. You should be good to go.

The idea of using that to locate instead of a stop is a good one, provided it is a positive location, and not too reliant on "feel" to get successive parts in the same spot. If it is, you can also center the vise before putting in the part, using the V itself, and thereby eliminate trying to indicate off the round sides. Then indicate off the flat side of the jaw, and offset from there. You should be good to go.

Homier Speedway 7x14 lathe

Grizzly G8689 Mini Mill

HF 4x6 Bandsaw, bench grinder and more

Years of experience wrecking things

Grizzly G8689 Mini Mill

HF 4x6 Bandsaw, bench grinder and more

Years of experience wrecking things

- rleete

- Posts: 62

- Joined: Thu Feb 02, 2012 5:22 am

- Location: Rochester, NY

Re: Where are we at?

Wow, I better be careful or I might actually learn something here!?  That's a great idea to index off the "V" in the jaw itself. Just from my recent experience in tramming the mill I can tell that piece of advice could save me considerable time and/or gnashing of teeth.

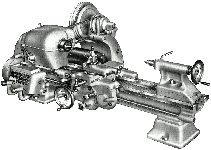

That's a great idea to index off the "V" in the jaw itself. Just from my recent experience in tramming the mill I can tell that piece of advice could save me considerable time and/or gnashing of teeth.  My fault though on not describing what the jaws were like in my original post. While I still haven't had a chance to measure or install them, here is what they look like (My vise is a 6" so the "V" should be large enough to do as we discussed.)

My fault though on not describing what the jaws were like in my original post. While I still haven't had a chance to measure or install them, here is what they look like (My vise is a 6" so the "V" should be large enough to do as we discussed.)

I actually bought them with this kind of project in mind. I've been enjoying the build and can see more engines in my future (as well as all kinds of other stuff). Before someone points out the obvious... Yes, I know I can mill my own vise jaws BUT with the price I paid for them ($80) and the time it would take me to get it done right, they were pretty hard to pass up.

Before someone points out the obvious... Yes, I know I can mill my own vise jaws BUT with the price I paid for them ($80) and the time it would take me to get it done right, they were pretty hard to pass up.

Just to let you guys know why I'll be posting more than getting anything done the next week or so as I've buggered up one of the disks in my neck. At the moment I'm just short of being ambulatory and haven't slept a wink since about Sunday (so much pain that I can't even lie down). I'm scheduled for some minor outpatient surgery on the 26th to see if we can un-bugger it a bit. Guess I've got to be more careful moving those lathes and mills around.

Guess I've got to be more careful moving those lathes and mills around.

Thanks again for the "tip". I can't tell you how much I appreciate getting advice like that from you, and the others who have built up their "knowledge bases" the old fashioned way.

-Ron

That's a great idea to index off the "V" in the jaw itself. Just from my recent experience in tramming the mill I can tell that piece of advice could save me considerable time and/or gnashing of teeth.

That's a great idea to index off the "V" in the jaw itself. Just from my recent experience in tramming the mill I can tell that piece of advice could save me considerable time and/or gnashing of teeth. I actually bought them with this kind of project in mind. I've been enjoying the build and can see more engines in my future (as well as all kinds of other stuff).

Just to let you guys know why I'll be posting more than getting anything done the next week or so as I've buggered up one of the disks in my neck. At the moment I'm just short of being ambulatory and haven't slept a wink since about Sunday (so much pain that I can't even lie down). I'm scheduled for some minor outpatient surgery on the 26th to see if we can un-bugger it a bit.

Thanks again for the "tip". I can't tell you how much I appreciate getting advice like that from you, and the others who have built up their "knowledge bases" the old fashioned way.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: Where are we at?

ScrapMetal wrote:and the others who have built up their "knowledge bases" the old fashioned way.

You mean like me, by ruining more barstock than most people do in a lifetime? I may never learn the right way, but I know dozens of ways not to do it!

Cronic back/neck pain is one of life's most miserable experiences. Get better soon.

Homier Speedway 7x14 lathe

Grizzly G8689 Mini Mill

HF 4x6 Bandsaw, bench grinder and more

Years of experience wrecking things

Grizzly G8689 Mini Mill

HF 4x6 Bandsaw, bench grinder and more

Years of experience wrecking things

- rleete

- Posts: 62

- Joined: Thu Feb 02, 2012 5:22 am

- Location: Rochester, NY

Re: Where are we at?

Thought I better update with my progress - not much.  I ran in to a bit of trouble, not with the build but with my spine. Seems I over-did it a bit and blew out one of the discs in my neck. It took me over two weeks to get in to the doctor. In that time I was unable to sleep, even for a few minutes as the most painful position for me is lying down. Go figure.

I ran in to a bit of trouble, not with the build but with my spine. Seems I over-did it a bit and blew out one of the discs in my neck. It took me over two weeks to get in to the doctor. In that time I was unable to sleep, even for a few minutes as the most painful position for me is lying down. Go figure.  In that time I was in agonizing pain. I'm sure some of you guys have dealt with that kind of thing yourselves, not fun!

In that time I was in agonizing pain. I'm sure some of you guys have dealt with that kind of thing yourselves, not fun!

Anyway, the doctors tried some kind of steroid injection into the disc but it didn't take (I'm still hurtin' in a big way, they tell me that pain meds don't work on nerve pain. Wow! Lucky me. ). The doctors told me that I need to have that disc taken out and the two vertebrae fused together (I do get a cool titanium brace put it. Look at me! I'm a cyborg!) as if I don't the loss of feeling and strength as well as the pain could become permanent due to prolonged nerve damage. Not much choice there so I did acquiesce to go under the knife. Hopefully I'll hear back from them on Monday about when it will be scheduled.

). The doctors told me that I need to have that disc taken out and the two vertebrae fused together (I do get a cool titanium brace put it. Look at me! I'm a cyborg!) as if I don't the loss of feeling and strength as well as the pain could become permanent due to prolonged nerve damage. Not much choice there so I did acquiesce to go under the knife. Hopefully I'll hear back from them on Monday about when it will be scheduled.

In the mean time, I'm not really supposed to be driving but I weaseled my way out of the house and made it to the office/shop. The wife is not happy and threatened what's left of my manhood if I go and do any work in the shop. Can I live on the edge or what?

I'm not doing anything on the build today but if I can get back in tomorrow or Monday I'll try and swap out the jaws on the Kurt vise and see if the "V" groove will be plumb to the horizontal axis (Do we use the term "plumb" in metalworking?) Just don't mention it to my wife.

Rleete may beat me to the "finish" yet but I'll still be trying to get those holes bored.

Hope everyone else is doing well,

-Ron

Anyway, the doctors tried some kind of steroid injection into the disc but it didn't take (I'm still hurtin' in a big way, they tell me that pain meds don't work on nerve pain. Wow! Lucky me.

In the mean time, I'm not really supposed to be driving but I weaseled my way out of the house and made it to the office/shop. The wife is not happy and threatened what's left of my manhood if I go and do any work in the shop. Can I live on the edge or what?

I'm not doing anything on the build today but if I can get back in tomorrow or Monday I'll try and swap out the jaws on the Kurt vise and see if the "V" groove will be plumb to the horizontal axis (Do we use the term "plumb" in metalworking?) Just don't mention it to my wife.

Rleete may beat me to the "finish" yet but I'll still be trying to get those holes bored.

Hope everyone else is doing well,

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: Where are we at?

Ron, that's rough. Nothing like constant pain to mess up your day. Here's praying for a speedy recovery.

Mike

-

Hawkeye - Posts: 44

- Joined: Sun Feb 05, 2012 10:04 pm

- Location: Kelowna, BC, Canada

Re: Where are we at?

Thanks much, I appreciate the thought.

I was hoping to get word on when we could schedule the surgery today (Monday) but no such luck. Wife is livid with the unresponsiveness and will light into the doctors and insurance company in the morning.

Sorry guys, didn't make it to the shop. I'll give it a try in the next couple of days maybe.

-Ron

I was hoping to get word on when we could schedule the surgery today (Monday) but no such luck. Wife is livid with the unresponsiveness and will light into the doctors and insurance company in the morning.

Sorry guys, didn't make it to the shop. I'll give it a try in the next couple of days maybe.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: Where are we at?

Sorry to hear about your neck, I hope you can getsome relief from the pain soon. Bill

- B34VD

- Posts: 26

- Joined: Sun Feb 19, 2012 3:54 am

Who is online

Users browsing this forum: No registered users and 1 guest