I am planning on making a couple of ARs for myself from 80% finished castings. I just finished making some vise jaws for my Kurt using Ray Brandes' drawings - https://arlower.ray-vin.com/ar15/ray%20 ... 0build.pdf

I"m sure that I'm over thinking this but now that I'm ready to drill some holes and mill out the receiver I'm looking for the "most accurate" or the "least error prone" way to do it. The way I see it I have three options for how to proceed.

One, fixture the receiver on it's side, locate the holes, drill all the way through and out the opposite side of the casting, then mill out the hammer and trigger cavity.

With this method, I know that drills can drift somewhat and the sides of the casting might not be perfectly parallel anyway. Holes on each side might not "match up" to where they should be.

Two, mill out the hammer and trigger cavity, fixture the receiver on it's side, locate the holes, and drill all the way through the casting out the other side.

This method has the same "problems" as the first but you are drilling through less material (less chance of deflection?) but when the drill hits the other side there is no pilot hole or punch mark and therefore a chance for the drill bit to "walk"?

Three, mill out the hammer and trigger cavity, fixture the receiver on it's side, locate the holes, drill out only that one side, flip the receiver over, re-indicate the holes, and drill the second side out.

The final method drills through less material, as "#2", but alleviates the chance of the drill "walking" as a spot drill can be used on both sides. Where this one is prone to error is simply in the indicating of the holes on both sides and how repeatable those measurements are.

All of the methods look to me to have both "pros" and "cons" but what I'm trying to find out is which "order of operations" would be the least prone to error and why.

Hopefully my explanation is adequate as to what I'm doing/looking for, so now I'd like to hear your thoughts.

Thanks,

-Ron

AR 80% lower build

17 posts

• Page 1 of 2 • 1, 2

AR 80% lower build

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

I don't think I want to get in to using a jig for this as jigs can have some issues of their own. If I was doing this on a drill press it might be the ticket but on a mill with DRO I can see some problems with it.

I should expand on this point a bit... I borrowed a jig setup from a buddy of mine to play around with and possibly use it as a model for some vise jaws I was planning to make. What I found was that using the jig setup was more trouble than it was worth. It got in the way of indexing off the casting itself forcing you to index off the jig and it's holes. The jig was made from 3 or four pieces that screwed together and not necessarily square, parallel, or perpendicular to where it should be plus it wasn't really designed to be clamped in a vise (go figure). It also made the depth of cut a bit of a guess and obscured where I was trying to cut.

That being said, I can see where I could make a one-piece jig for just drilling the couple of holes that need to be drilled but I'm still not sure that it would be more accurate than using the mill/DRO/indicators method when all is said and done. I'm not too sure that I would be building a better mouse trap than the guy who designed the original jig.

Thanks for the suggestion. I'll still keep it as a "plan B".

I should expand on this point a bit... I borrowed a jig setup from a buddy of mine to play around with and possibly use it as a model for some vise jaws I was planning to make. What I found was that using the jig setup was more trouble than it was worth. It got in the way of indexing off the casting itself forcing you to index off the jig and it's holes. The jig was made from 3 or four pieces that screwed together and not necessarily square, parallel, or perpendicular to where it should be plus it wasn't really designed to be clamped in a vise (go figure). It also made the depth of cut a bit of a guess and obscured where I was trying to cut.

That being said, I can see where I could make a one-piece jig for just drilling the couple of holes that need to be drilled but I'm still not sure that it would be more accurate than using the mill/DRO/indicators method when all is said and done. I'm not too sure that I would be building a better mouse trap than the guy who designed the original jig.

Thanks for the suggestion. I'll still keep it as a "plan B".

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

Didn't have time to do much in the shop today as I took my wife to the shooting range to put many little holes in a target or two. She was chomping at the bit to try out the new grip I installed on her Ruger LCP. A good time was had by all. :biggrin:

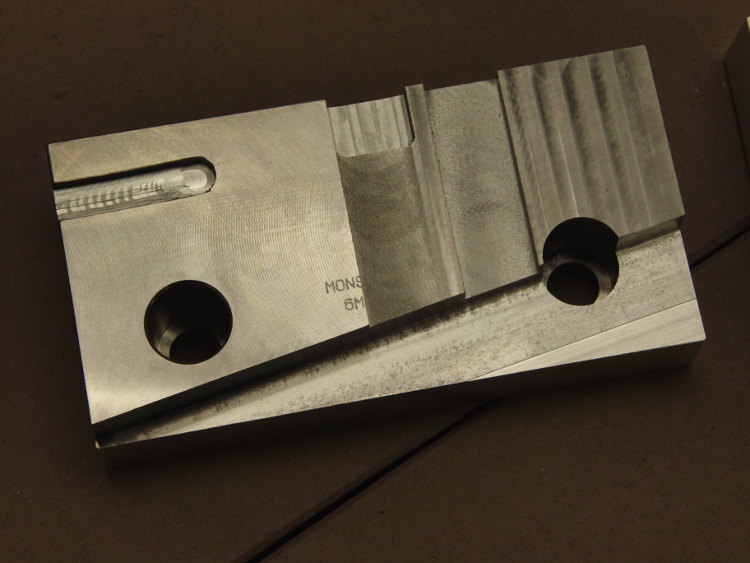

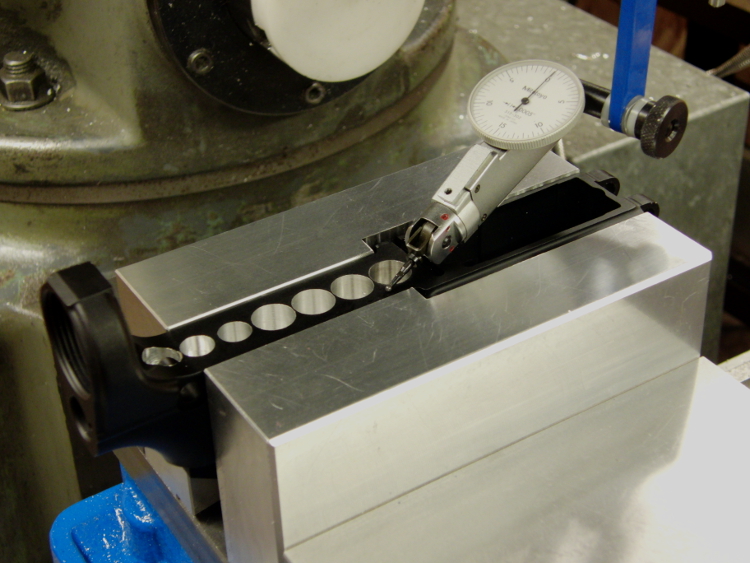

I did take the time to take some pictures (not the best quality but what the heck...)

I started with a set of 6" x 3" x 1.5" aluminum soft jaws from Monster Jaws, fired up the mill and the chips were a flyin'.

Here's a couple of shots with the lower receiver sitting in them...

I expect that they will work out nicely.

-Ron

I did take the time to take some pictures (not the best quality but what the heck...)

I started with a set of 6" x 3" x 1.5" aluminum soft jaws from Monster Jaws, fired up the mill and the chips were a flyin'.

Here's a couple of shots with the lower receiver sitting in them...

I expect that they will work out nicely.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

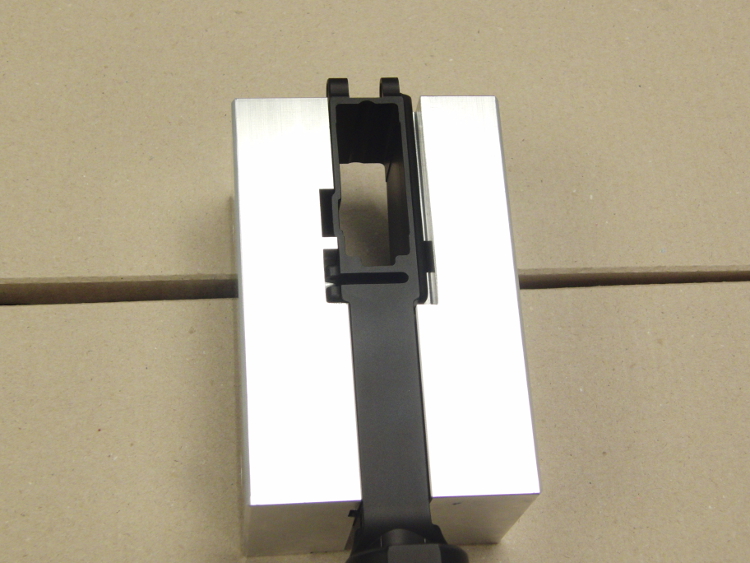

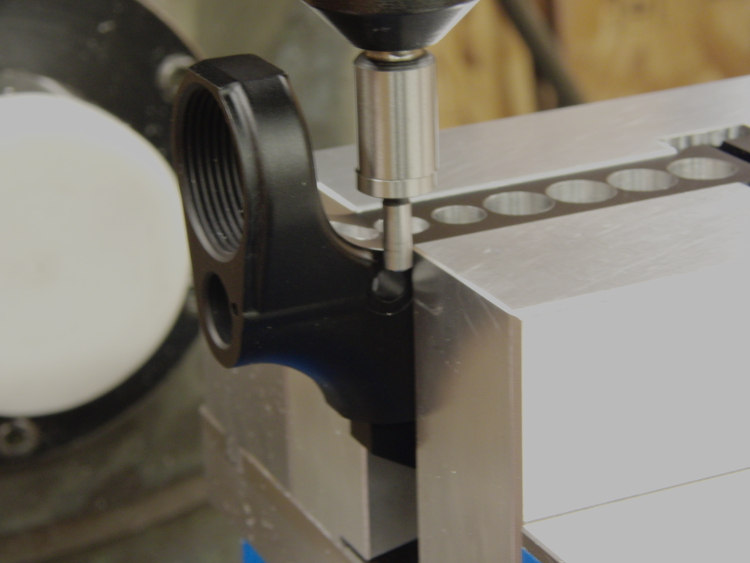

Got to work in the shop for a couple of hours today. Installed the new jaws on the Kurt and completed the first operation (drilling).

I didn't get a picture with the DTI but it is at this point that I put a test indicator on the lower casting to make sure that the top of it was parallel to the table.

Here is a shot of the completed "first operation". I set the quill stop for the proper depth and then "went to town" on drilling.

Hopefully in the next couple of days I'll be able to get an end mill or two in there and finish milling out the cavity.

-Ron

I didn't get a picture with the DTI but it is at this point that I put a test indicator on the lower casting to make sure that the top of it was parallel to the table.

Here is a shot of the completed "first operation". I set the quill stop for the proper depth and then "went to town" on drilling.

Hopefully in the next couple of days I'll be able to get an end mill or two in there and finish milling out the cavity.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

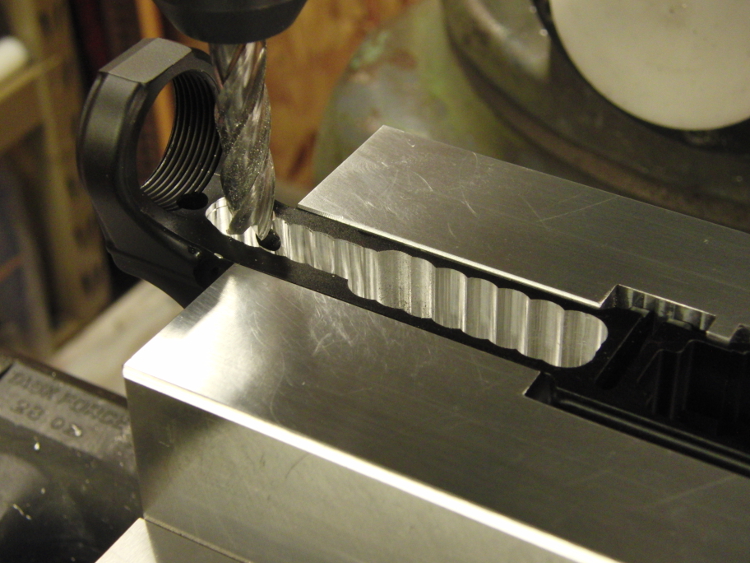

Then next step will be to go in with a long 7/16" end mill and plunge/rough out the remaining areas then do a finish cut with a "bull nose" 7/16" end mill. I use the "bull nose" or corner radius end mill to finish up as I really dislike sharp corners in deep pockets. The radius corners are easier to clean and, not that it really matters, are also "stronger".

Thanks,

-Ron

Thanks,

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

Just a little update. I was able to rough and finish the first of the lowers today. The finish isn't as pretty as I would like but I'll work on that for the next one. Now I have to get it back in the vise and mill the hole for the trigger as well as drill the holes in the sides.

-Ron

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

I didn't get a lot done today. I had to take a couple of tenths off of the rear area that the tab on the upper fits in to. I think when I milled it the first time I let it get a bit dry and the aluminum built up on the cutting edge just enough to not let it cut properly. It's all better now.  That, and I cut out the trigger slot. Just did it "fast and dirty" with a 5/16" ball end mill. Positioned it at one end, plunged through, then just routed the rest of the slot. Not worth taking a pic of.

That, and I cut out the trigger slot. Just did it "fast and dirty" with a 5/16" ball end mill. Positioned it at one end, plunged through, then just routed the rest of the slot. Not worth taking a pic of.

I'm waiting a bit to do the holes for the trigger group. I'm a bit on the "anal retentive" side for accuracy especially for placing and sizing holes for something like this (Even though it might not sound like it after I described how I did the trigger hole :rolleyes: but these holes are important). I am waiting on some reamers to arrive so I can drill then ream the holes to size. I'll have some more pics when that is under way.

-Ron

I'm waiting a bit to do the holes for the trigger group. I'm a bit on the "anal retentive" side for accuracy especially for placing and sizing holes for something like this (Even though it might not sound like it after I described how I did the trigger hole :rolleyes: but these holes are important). I am waiting on some reamers to arrive so I can drill then ream the holes to size. I'll have some more pics when that is under way.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

One thing I would consider doing if (or when) I build another set of jaws for 80% castings, I would start by making wider, over-size jaws, maybe about 8". I would drill out points in both halves of the jaws in the pivot pin and take-down pin areas then press fit four pieces of drill rod (or some harder metal rod the size of the pins) in them. When closing the jaws on the casting the pivot point and take-down holes would engage the pressed-in rods. With the leveling/indexing of the casting being done on the pins it it would save me from having to put a DTI on the casting and getting it level with the table/vise/mill. You'd have to be careful to make provisions for touching off the pivot pin with and edge finder as well as access to the take-down holes for the same reason as I use that area to establish the center of the casting once it's in the vise. Hopefully that was understandable, pictures or drawings would be better but I have neither at the moment.

So far the jaws have worked fairly well.

-Ron

So far the jaws have worked fairly well.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

I decided to wait on milling out the last couple lowers until I have some new end mills (due any time now) and still waiting on the spot drills. Quick rant - It sucks being in an area of the country where there is virtually no manufacturing and you have to order all your tools.

It's not like there are a lot of choices out there for a 7/16" corner radius end mill with a 1.25" - 2.0" LOC as it is. I could do it without the big LOC but it does nicely clean up the deep pockets. FYI - Maritool or Titan seem to be the places to look. If anyone else has other sources I'd be glad to hear about them.

-Ron

It's not like there are a lot of choices out there for a 7/16" corner radius end mill with a 1.25" - 2.0" LOC as it is. I could do it without the big LOC but it does nicely clean up the deep pockets. FYI - Maritool or Titan seem to be the places to look. If anyone else has other sources I'd be glad to hear about them.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

Re: AR 80% lower build

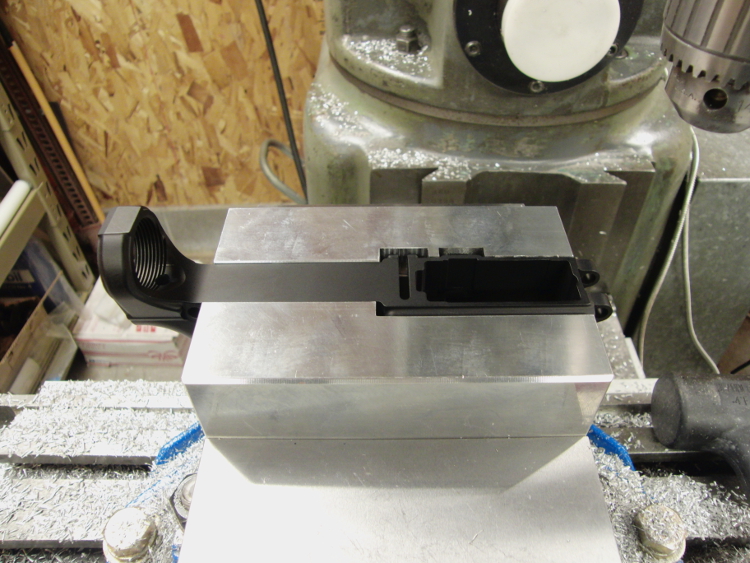

Figured I'd do a quick follow-up as I have a couple more shots of the whole procedure...

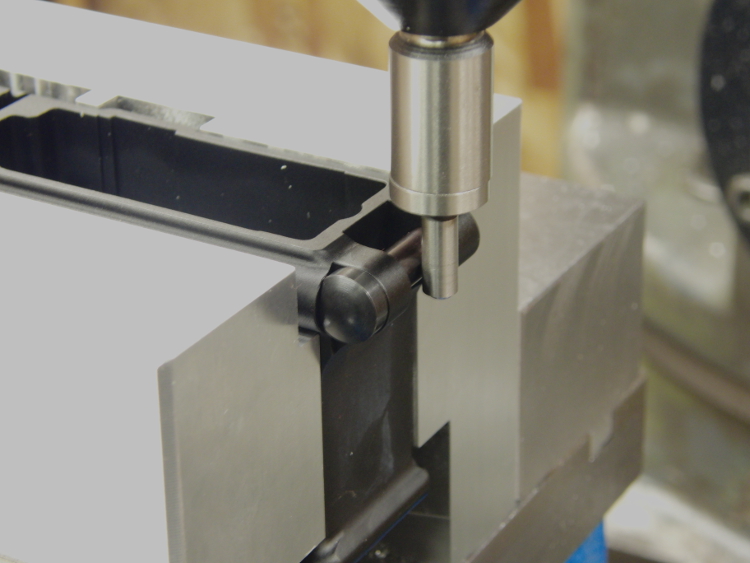

Here I put the drilled out casting back in the vise and used the DTI to make sure it was true with the mill.

I installed the pivot pin and touched off of it with the edge finder to set the "0" on my X-axis.

To set the Y-axis "0" I touched off one side of the casting, set the zero on my DRO, then switched to the other side and used the "1/2" distance function to find the center line.

Finally, here is a shot just as I'm finishing up the plunge/roughing out.

-Ron

Here I put the drilled out casting back in the vise and used the DTI to make sure it was true with the mill.

I installed the pivot pin and touched off of it with the edge finder to set the "0" on my X-axis.

To set the Y-axis "0" I touched off one side of the casting, set the zero on my DRO, then switched to the other side and used the "1/2" distance function to find the center line.

Finally, here is a shot just as I'm finishing up the plunge/roughing out.

-Ron

Wells-Index 860 Mill

South Bend 11" Lathe

Queen City Shaper

South Bend 11" Lathe

Queen City Shaper

-

ScrapMetal - Site Admin

- Posts: 225

- Joined: Thu Feb 02, 2012 3:39 am

17 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: No registered users and 10 guests